A threaded rod is used to hang and stabilize structures in various projects. However, a common challenge is that it is only available in specific lengths that may not suit specific projects. Consequently, you may need to resize it without damaging the thread.

One drawback of cutting threaded rods or bolts is the burrs on the end of the stud which make the fastening of the nuts difficult. This article provides step-by-step instructions on how to cut a threaded rod from a long bar to come up with a clean-cut slate.

Table of Contents

Steps to Cut a Threaded Rod

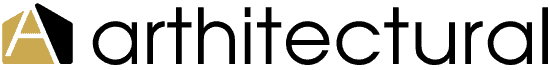

Materials:

- Safety gear (gloves and protective glasses)

- Clamp or vise

- Ruler

- marker

- Bolt cutter, hacksaw, and Dremel with metal cutting blade

Depending on the size and material of the threaded rod, you may need different cutting equipment. Manually operated tools such as bolt cutters or hacksaws might suffice for thinner threads.

However, power tools such as Dremels or grinders with metal-cutting blades are recommended for thicker threads.

Below are the detailed steps for cutting using different threaded rod cutters:

Step 1: Preparation Materials

Ensure all the necessary materials are prepared before cutting threaded rod to avoid any interruption when the cutting begins.

Also, wear protective gear to shield yourself from potential hazards that may arise like sharp edges and sparks, especially when using power tools.

Step 2: Measure Thread Length

Measure the desired length of the threaded rod using a ruler or carpenter’s tape and mark the cutting line with a permanent marker for it to be easily seen.

Step 3: Cut the Threaded Rod

1. Use of bolt cutter

You can manually cut smaller and thinner threaded bolts with a bolt cutter. You only need a firm grip and strong hands to successfully cut the bolt to your desired length.

- Thread a couple of nuts into the threaded bolt before inserting it into the bolt cutter.

- Cut the bolt to length by applying pressure to the cutter. Squeeze it as hard as you can until the bolt cuts down.

- The new end will have rough edges that could hinder the smooth fitting of the nut onto the threads. Nevertheless, this is when the nuts you placed earlier come in handy. Loosen them to straighten and align the damaged threads affected by the cut.

2. Use of hacksaw

A hacksaw is another commonly used tool to shorten a bolt or threaded rod that can handle any size of threaded rod.

- To cut the rod, secure it in a vice or clamp and hold the hacksaw with one hand on either end, assuring a solid grip.

- Start cutting slowly, ensuring the blade stays in contact with the rod while you slide it back and forth. Keep your focus and maintain a steady hand as the blade may change course when you slack.

- Remove the rod from the vice once the desired portion is cut.

One common problem when cutting threaded rods is voluntary spinning during the cutting. However, this can be avoided by clamping a wooden block into the vice. Stick the rod into the side of the block tightly so that it cannot be moved the moment you’re cutting.

3. Use of Dremel

The Dremel rotary tool is an exceptionally versatile and indispensable power tool that cuts bolts to the desired length. The tool model 3000 and above can easily cut different types of metals up to ⅔ inches in size.

- To start cutting the threaded rod with a Dremel, simply adjust the RPM to your desired speed. A higher RPM is ideal for achieving efficient cutting. However, it is advisable for newbies to start with a lower RPM in order to help them adjust and adapt to the correct use of the tools.

- Always remember to secure the nut onto the bolt before trimming the end. This vital step safeguards the threads from potential harm. It guarantees seamless and effortless thread alignment on the newly cut end.

If you need to cut a few threaded rods, it is recommended to use these tools. However, if you plan to cut many rods, using more powerful and heavy-duty tools like grinders and chop saws is more appropriate.

Step 4: Do the Finishing Touches

Finishing touches include deburring and chamfering.

Deburring removes ridges from a cut line, while chamfering creates an angled surface and removes a damaged thread end. This technique improves the starting point of threads, making them smooth and ready to use.

For this task, sandpaper, hand file, or grinder can eliminate sharp edges, burrs and make a smooth angled surface on the newly cut line.

A chamfer threaded rod allows easier fastening of nuts onto the rod or bolt while reducing the occurrence of injury from rough edges.

Conclusion

Cutting threaded rods demands precision and carefulness, regardless of the chosen method. Mastering how to cut a threaded rod can save you valuable time wasted on frequent trips to the shop to replace bolts or incorrect thread lengths. It also empowers individuals to take on more do-it-yourself projects that require this skill.

Remember to exercise caution and prioritize safety when working with metal. Also, it is crucial to ensure the metal edges are cooled down before handling the newly cut rod.

Hi, I am Roseanne Jones, an aspiring home designer that wants to make you feel more at home with your new house.With nearly five years of redecorating old residents and arranging new ones, I am confident that I can give you the best advice on your lovely place.