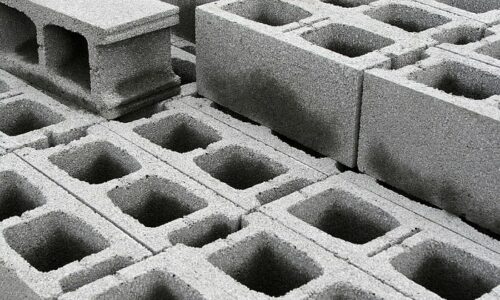

Building blocks may look like each other, but they serve different purposes for construction.

If you’re considering using a cinder block and don’t want to mess up your project through overloading, make sure to know how much weight can a cinder block hold.

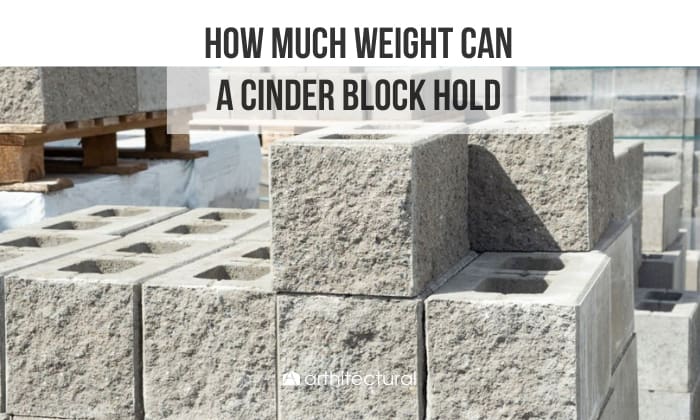

Technically, cinder blocks, compared to other concrete blocks, are lighter and can withstand at least 1,700 pounds per square inch (PSI).

Table of Contents

- How Much Weight Can a Cinder Block Hold?

- Depending on the Size of the Cinder Blocks

- Factors That Affect the Weight a Cinder Block Can Hold

- A Cinder Block and a Concrete Block: What is the Difference?

- Tips to Transport Cinder Blocks

- Cinder Blocks’ Usage Around the House

- Frequently Asked Questions

- Conclusion

How Much Weight Can a Cinder Block Hold?

ASTM standards say that an individual concrete block must be able to hold at least 1,700 PSI per square inch.

Cinder blocks can differ in sizes, depending on the manufacturer. Hence, the cinder block strength could be far more than the minimum withstanding capacity that ASTM requires.

In case you are wondering how much does a cinder block weigh, the standard size weighs 38 pounds or 17 kilograms.

One of the most common questions is can a cinder block hold a car. To directly answer this question, yes, but not as a permanent support.

Cinder blocks can be a temporary substitute for jack stands when holding a car. However, if you have the ability to own or borrow a jack stand, you should do so. This is because cinder blocks may have an excellent compressive load capacity, but they are porous and prone to breakage when you use them as a long-term car stand.

Also consider that the place where you put the block can also affect how much weight it can hold. For example, if you place a cinder block on soft soil where you are trying to repair your car, the soil can shift the block and eventually damage the car.

However, some people use bricks to hold their vehicle while repairing it, and you should remember that a cinder block is different from a brick.

So how much weight can a brick hold? A traditional clay brick is usually made of sand, lime, concrete materials, and clay, and can hold as much as 3,000 PSI.

Depending on the Size of the Cinder Blocks

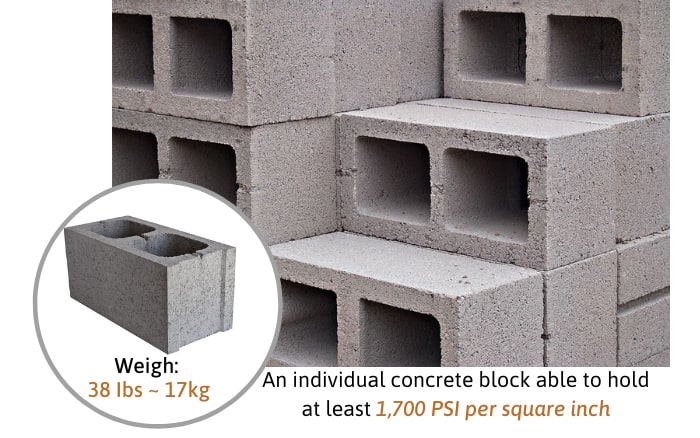

Of course, the cinder block weight capacity depends on the size of the cinder blocks you use.

The most common size for a cinder block is 16 inches by 8 inches by 8 inches (LxWxH).

However, cinder blocks are available in different sizes. They commonly have a width of 4, 6, 8, 10, or 12 inches.

The shape of a cinder block sometimes looks different from a typical rectangular block with two holes in the middle.

Cinder blocks are available in shapes like: Hollow Stretcher, Hollow Corner Sash, Solid Pier, Solid Corner Sash, Hollow Pier, 45-Degree Angle, Hollow Cap, Solid Stretcher, and many more.

It is relevant to know that shape is also a factor when it comes to knowing how strong are cinder blocks.

For example, hollow cinder blocks are usually weaker than a solid cinder block (withstanding on average 1700 psi per square inch vs. 3000 psi per square inch or more). What makes a hollow cinder block desirable in some applications is its ability to have a rebar inserted and be filled with a strong concrete mix.

If you are wondering what a pier block hold, you can use it in cases where the hassle and effort of inserting rebars and concrete mixes is not considered, such as in making fire pits.

Factors That Affect the Weight a Cinder Block Can Hold

Although there is standard information on how much weight a cinder block can hold, still, its purpose mainly depends on several factors such as the following:

1. Structural Context

The weight of the block might depend on the structural setup you are using it for. Some of the examples are:

- Weight Distribution

Spreading the application of a weight on an area makes the blocks able to carry a heavier load than when you apply the weight directly on a concentrated point of the block.

For example, when you use cinder block support columns, the weight that the block carries will be higher than that of a block that is supported by tiles or slabs which are wider than the columns.

- Material Combination

Using several materials with cinder blocks make the blocks stronger than their normal capacity.

This is because the weight that the blocks should be holding is also distributed to the material you combined with it.

Take for example, a wall of cinder blocks constructed with steel beams can hold more weight than the sum of the capacity of all the blocks (alone).

2. Material Considerations

Most of the time, the holding capacity of the block depends on the materials used to make it, its form, and several more factors.

- Raw material components

The quality of the cement and the aggregates used in making the block determines how solid the units can be.

You must know whether the producer of the blocks is careful in terms of their storage method, consistency testing, seclusion of chlorides and sulfates, and the quality of the water used in making the cinder blocks.

These are necessary for a company to become a trusty cinder block manufacturer.

- Entrapped air

Although they say that the entrapped air in the block improves its workability, you must still keep in mind that this entrapped air reduces the strength of the block by 5%.

- Temperature and relative humidity

A cinder block is more porous as compared to concrete blocks. This is why you need to consider the temperature and humidity control of the manufacturer whom you are buying your block from.

In this aspect, dry environments usually speed up the process of drying and hardening for the blocks. This process also ensures that the cinder block will be less porous.

A Cinder Block and a Concrete Block: What is the Difference?

Your first glance at a cinder block and a concrete block will confuse you due to their almost identical appearance. However, their components make them different, which allows them to have their uses.

A cinder block is made of concrete and coal cinder, which is why it has a lighter weight, while a concrete block is made of steel, stone, and cement, which makes it heavier.

Furthermore, cinder blocks are only used in small projects, while concrete blocks are used in buildings and big construction because the concrete block strength is a lot higher than that of cinder blocks.

Regarding repairs and maintenance, cinder blocks require many repairs compared to concrete blocks, which sometimes do not need repair at all.

It is also helpful to know that cement blocks differ from concrete ones. They differ in the aggregates used; cement blocks use fly ash, while concrete blocks use stone.

Tips to Transport Cinder Blocks

You might have seen some people lay a concrete block hold on its side, which might make you think that it is that easy to carry a block.

However, that is not the case. Moving cinder blocks from one place to another is more complicated than you might think.

We recommend you consider the following methods or tools for your convenience:

- Dolly

Some people think that a dolly is quite expensive, and that is actually right, especially if you are using it to transfer cinder blocks for one project.

However, if you often carry things here and there, investing in a dolly is worth it, mainly because cinder blocks are heavy if lifted one by one.

- Pipes

If you do not have much money for a dolly and have a lot more time to make some extra effort, you may also roll the blocks using PVC pipes. Just keep moving every pipe to keep the cinder block inching forward.

- Sliding or Flipping and Hand Carrying

If there is an available flat surface, you may also choose to slide the blocks from one place to another.

You might also use a cloth to help them slide more efficiently and smoothly. Refrain from sliding the blocks as quickly as possible, since this can cause further problems like damage to your flooring.

Moreover, you may also choose to flip or hand-carry the blocks. However, this takes a lot of time and effort to finish.

Cinder Blocks’ Usage Around the House

Despite being weaker than concrete blocks, cinder blocks have a lot of uses around the house.

These blocks can help you improve your residence, from building walls to grills and even raised beds or book shelves, though you can use a cinder block shelves alternative like metal crates instead.

Cinder blocks are also used for constructing garden walls or fences, fire pits, counter shelves, mini storage, and more.

Frequently Asked Questions

How much does a cinder block cost?

A standard cinder block cost around $0.97-$3. It is pretty affordable for its size (16 x 8 x 8 inches) because of its components.

How long can a cinder block last?

On average, a cinder block can last 100 years, since it does not rot, become weak like a block of wood, or grow mold regardless of the weather.

Is it safe to drill into cinder blocks?

Yes, it is safe. We recommend you use a rotary hammer drill for a faster and smooth drilling experience into the cinder blocks.

You may also use a regular drill, but it might take a lot of effort and time to finish.

Conclusion

Before starting a project, make sure to know the quality of the materials you will use, not only to make every penny worth it and the construction project last long, but also to ensure the safety of everyone on the job.

Many people have been using cinder blocks in building their homes, and you must first know how much weight can a cinder block hold to prevent further mishaps and elevate your house’s design or construction.

Hi, I am Roseanne Jones, an aspiring home designer that wants to make you feel more at home with your new house.With nearly five years of redecorating old residents and arranging new ones, I am confident that I can give you the best advice on your lovely place.